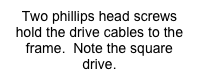

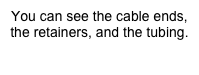

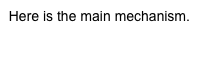

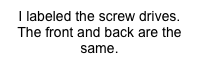

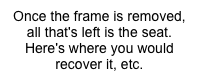

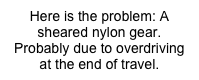

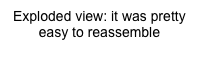

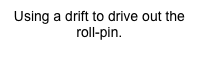

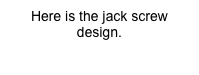

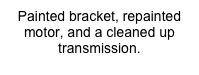

Back in November of 2001, I decided to fix the non-moving axis on the seat mechanism and see what I could do about the noise. It was a pretty simple operation, although there were many little steps. Here is the whole thing photographed so that you can rebuild yours with confidence.

'66 Seat Mechanism Rebuild